The model's story: The Fiat RS14 floatplane was one of the most elegant and beautiful aeroplane of the Second World War era. Plagued with structural problems, she only saw a limited and short timed service with the Italian Regia Aeronautica's maritime recce units hence, I think, the reason why she has never been reproduced by any of the major model manufacturers. Only short runners offered some limited production, hard to find and somewhat inaccurate in rendering. I had purchased one Aviation Usk in the late 80ies but I was unable at that time to make a good model. Even now I am nothing more than an average modeller, not surely a master one. That model did not find a place in my showcase and was relegated into my garage, waiting for better days. Years later the days arrived indeed, but worst ones as a nearby stream brought three meters of muddy water. When shoveling debris out into a truck, half a wing, one tail surface, a float and some more parts of the kit emerged out of the mud. Waters had brought away dozens kits with them, a lot of books and all my decal sheets; I decided that I would have rebuilt the Fiat one day starting from the saved parts, as a kind of revenge for having lost the bulk of my collection.

I decided that when making my new model most of the errors of the Aviation Usk would have had to be corrected, and consequently I would have had to make new wings of right chord, correct the fuselage and add side windows, redraw the tail surfaces contour, make new engines with cylinders rows, revise the floatplanes, provide new propellers and on. So, on January last I have begun making my RS I had make some resins earlier and I so decided to make a full resin model starting from the few parts I had kept and making the others from scratch or of my own. Making the moulds and casting the parts has not been an easy affair. I had to practise how to handle silicone and resin in the right, balanced quantities and how long to wait to let moulds and resin parts to catalyse and dry up correctly. A quantity of moulds and of casted items were disposed of and you don't know how costly the silicone is until you waste it. For instance near 400 grams are needed to make the mould for a half wing, should the silicon be prized 60 euros a kilo you can calculate how costly making a resin model is, taking into consideration that two or three or even more moulds are to be attempted to arrive to obtain a satisfactory result. What do you think of several hundred euros? But I'm a Capricorn and I did not deflect from achiving my goal, whatever the cost in money and time could have been. More than seven months were required, and very often I worked on my project for more hours per day and with the same concentration and determination as when performing my job in my office before retirement.

Last but not least, I must thank my wife who continued going on with cooking and handling our home as usual when I was submerged into my work so deeply as, or more than, an atomic submarine. She actually roared to me more than once but allowed me to complete my job.

The assembly: Well, now some words on the kit itself. The kit is composed of more than 60 pieces; the body is made of solid polyurethane resin, the transparencies are vacuum formed but the dorsal gun turret that is of transparent resin to give sufficient base to install the gun and its counterweight bar and the base made of wood. A home made decal sheet is enclosed with national insignias and squadron service number and badge for a machine from the 170th Squadron.

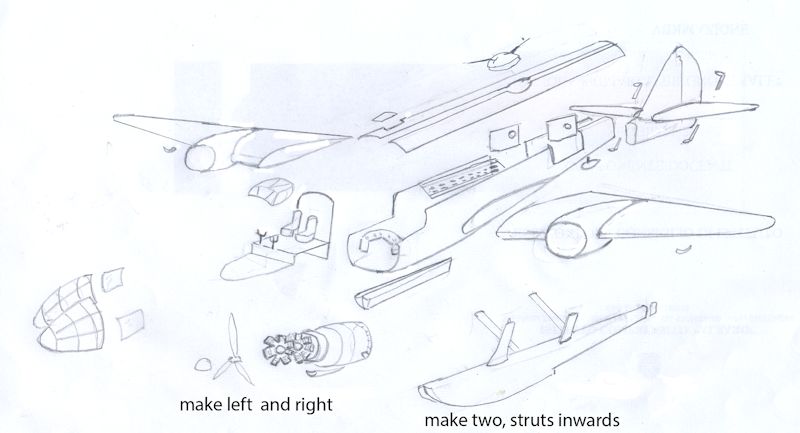

All pieces are simply obtained per gravity because I have no space nor skill to operate vacuum machines or the like. Nevertheless I obtained some pieces having undercuts like the cylinder rows with satisfactory results. I prepared the symmetrical parts in such a way that one could be used to obtain the left and the right or the upper and the lower components. For instance: I prepared the wings in such a way that the upper right could be good for the lower left one and floats are made of a right and of a left half, good for either the right and left assembly. This let me a good saving in time and money and gave identical parts for both sides of the model. The assembly is simple and straight forward because I prepared the components with ease of moulding and ease of assembly in mind. The simplest is moulding, the simplest is assembly I guess.

The fuselage is to be prepared at first with its roof and cockpit in place, then the dorsal halves of it are to be glued into position together with the transparent dorsal gun turret and dorsal clear panel, last the tail surfaces are to be added. Now let's add the ventral gondola if required (this piece of equipment was actually added provided the mission profile so required), the half wings and the floats and struts components. A hole in wing underside and a pin in float front strut secure the correct alignment of assemblies. Now glue the cylinders rows and glue them to the front of wing engine nacelles, add the cowlings and lower air ducts and finally cement the propellers and related hubs. Do not forgive that propeller rotated inwards the fuselage. Now add the fuselage side windows and a number of little items such as the ailerons actuators, the tail surfaces counterweights, the balloon shaped antenna. At this time the most difficult part of assembly: the preparation of the cockpit canopy, of two nose transparencies and nose transparent panels. Cut the parts carefully for only one set being supplied and locate and cement them with the help of small strips of transparent scrap (and with the help of a great deal of patience!)

The kit is now near to completion: the pitot tube, the radio antennas and the machine guns and counterweight bar are to be found from the anyone's spare box. Camouflage is a simple affair: either grigio azzurro scuro 3 FS 36118 or verde mimetico 1 FS 34258 overall for upper and side surfaces, grigio azzurro chiaro 1 FS 36307 for undersides. The bottom of the floats was dull black, the interiors verde anti corrosione.

Due to service under marine conditions, paint was prone to deteriorate under operational conditions and the back of the aeroplane finish quickly faded into a dull, chalky and lighter rendering. The white cross on the rudder was often touched up for being the nation insignia and consequently the rudder finish was often more fresh, dark and neat than the surrounding areas.

The decal sheet provides national insignias for the wings and sides of nose; after the fall of the regime on july 25th 1943 they were officially cancelled therefore these decals may not be added or overpainted with the nearby color.

Well, the RS14 is now finished, place it on its wooden base and open your showcase!

My kit is a home made one, prepared in a very short run with a lot of love and passion for our common hobby but in a strictly "amateur" manner. Though I tried making my best because we all love having fine models, I am aware it can not stand up the quality of an Hasegawa or Dragon product. That's natural of course.

But everyone's skill and passion is however enough to get a fine looking kit out of those yellow parts and to build a plane that can be proudly exposed into everyone's showcase, side by side with the kits of celebrated professional Manufacturers. A little bit of extra work may be required for sanding, smoothing or filling some superficial mishap but we are true modellers, not glue-anything-together-men, isn't it?

Please consider this in end: no manufacturer is currently offering the Fiat RS14, if you like this machine for your collection you can get yours now!

I thank you for your kind attention and am ready answering all of your further questions you will email to my address: moresco.giovanni@libero.it.

Giovanni Moresco, Genua, Italien